The Jobenomics Team formed eCycling USA (www.eCyclingUSA.com) to address US environmental challenges caused by millions of tons of electronic waste (e-waste), and provide a revenue stream for metropolitan-based Jobenomics community based business generators that are designed to create 1,000 new, small, inner-city businesses per year (see Jobenomics-Harlem blog entry).

E-Waste Challenge. Worldwide revenues from e-waste recovery were reported to be $8.5 billion in 2009 and are expected to grow to $13B by 2014. Currently, 3 million tons of e-waste is produced annually in the USA. Less than 20% of this amount is recycled and the annual amount will exceed 10 million tons by 2017. A 2009 survey printed in the Journal of Environmental Management states that 747 million electronic items are stockpiled by US households or more than 4 times as much as official US Environmental Protection Agency (EPA) estimates. The EPA reports that 2.25 million tons of TV’s, cell phones and computer products ready for end-of-life management, 18% was collected for recycling and 82% was disposed of in landfills or sent overseas for aftermarket applications. Almost 90% of the exported US e-waste is to China, Nigeria, and India. The US federal government is beginning to restrict e-waste exports and state governments are limiting e-waste in landfills. While US recyclers have begun the task of managing e-waste, it could take 40 to 50 years to recycle at current rates of recycling. Of the 3,321 US recycling companies only 78 provide some form of shredding, and none can process both white ware and eScrap at the rates that the eCycling USA/Adelmann system can.

eCycling USA™ is licensed by Adelmann Unwelt GmbH of Germany to implement “turnkey” e-waste plants in the USA. Adelmann is the world leader in manufacturing and providing turnkey recycling systems that reduce e-waste to commodity powders and pellets. 60 Adelmann plants are operational in Europe. There are no comparable plants in America that shred both white ware (e.g., refrigerators) and eScrap (e.g., computers), and decompose this e-waste into raw materials (copper, aluminum, iron, plastics, etc.). eCycling USA systems can shred an appliance as large as a refrigerator in minutes into pellets or powders. These pellets/powders are aggregated by raw material type and packaged for sale to commodity buyers. eCycling USA’s processes are accomplished in a closed environment to prevent any leakage, like CFCs, into the environment. A total of 100 plants are envisioned with a substantial amount of plant manufacturing accomplished in the USA.

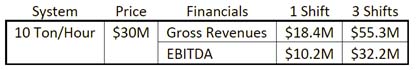

Strategic Partnerships. eCycling USA is seeking strategic partnerships for locating the first 10 plants for US metropolitan areas. These plants are capable of processing 10 tons/hour of e-waste. The cost of a plant is $30 million, of which eCycling USA will provide $14 million, leaving $16 million of debt or equity financing for strategic partners and investors. Turnkey plants can be constructed within nine months on one acre of land in an 80,000 square foot building with 40 foot ceilings. eCycling USA has located numerous brown-field (e.g., vacant warehouses) sites in several major US metropolitan areas and has commitments by local government officials to expedite permitting as well as providing grants for infrastructure improvements. A typical plant will be capable of employing 500 personnel.